Posted by SteveBeaver on Monday, April 28, 2008 @ 10:26 PM:

It seems to me (without the benefit of in depth research) that it is not easy to fit an engine driven charging system to an unmodified Rectmo engine. There is very little space at the prop end and since the prop hub is very close indeed to the crankcase, there seems to be no room for a pulley to drive a farm tractor alternator or generator. At the other end, the magneto and its drive system would seem to preclude the installation of a pulley too. Assuming we don't want to go to the length, weight and expense of installing a Diehl accessory case and dynamo system, what else might work? (At night)

Is the VW distributor drive intact on a Rectimo? What if we were to obtain a suitable distributor, throw away the cap and most of the innards, then cut it down to the minimum possible height. Really all we are left with is a rotating shaft. Add some nice low profile rare earth magnets and a stator and we have a source of AC power. Not much, perhaps but 2 amps is all it takes to run a radio, transponder and LED position lights and that doesn't take too much science at 1400 rpm.

Then again, as they say in the Linux world, if it's worth doing, someone will have already done it. Have they? If not, perhaps (as usual) I am overlooking something important.

How else might we generate some electron flow without major modification work?

Posted by andy1 on Tuesday, April 29, 2008 @ 05:47 AM:

Hi Steve,

The distributor gear is installed in Rectimo crankshaft as it is a oil-heat fitted part that is needed for proper installation of the shaft parts and correct end play (see part 6 in figure). In theory your idea might work if you can get the system low enough to fit under hood. I'd be very interested to hear more if you decide to plan the thing.

-Antti-

[Edit by andy1 on Tuesday, April 29, 2008 @ 05:56 AM]

--------------------

***** Antti Laukkanen, Helsinki, Finland - RF4D OH-371 - RF4D OH-370 - RF5 OH-386 *****

Posted by Collin on Tuesday, April 29, 2008 @ 12:57 PM:

Hello,

My Rectimo serial #150 had all the distributor stuff installed. Here is want I have been working on. I have been testing small stepper motors. The first one was about 1 amp here is a picture of one that should be about 2 amps. I think I can keep it low enough to fit the std cowling. At 1,500 rpm (3,000 rpm crank there are about 14v. So they will not need a regulator just diodes. 35mm x 42mm ( 1.340" x 1.650" )

Posted by rshoover on Tuesday, April 29, 2008 @ 05:00 PM:

Dear Steve (and the Group),

Over the past sixty years a remarkable number of things have been stuffed down the distributor holes on VW & Porsche engines. Aside from the Vertex magneto, the standard ignition on lots of VW industrial engines and Mother's Milk for flying Volkswagens, there was the infamous Siamese distributor -- two identical Bosch distributors side-by-side, the second driven by a cog-tooth belt -- as well as dual point distributors, distributors fitted with a pick-off for a mechanically-driven tachometer -- and even a couple of dynamos.

An Australian fellow adapted a large bicycle dynamo to be driven by the distributor shaft. A Brazilian used the tiny permanent-magnet dynamo from a motor scooter.

(I'm guilty of modifying the Nippondensu distributor from a Toyota to work happily on the VW engine.)

A major disadvantage of using the distributor-drive to power a dynamo is it turns at just half the speed of the crankshaft. If you need an appreciable amount of power you'll need fairly heavy windings, powerful magnets and a rotor of significant diameter. And like all other small-scale dynamos, the thing is only about 50% efficient.

In the stock configuration, driving a regular VW or Bosch distributor, the load is represented by the two plain bearings of the distributor's driver-gear (ie, down inside the crankcase), the drag of the Micarta oil seal washers, the plain sleeve bearing(s) in the distributor's shaft, the torque needed to actuate the spring-loaded contact points, and the drag of the graphite button in the top of the distributor cap. When properly maintained the useful life of the distributor was about 30,000 miles due to wear of the Micarta seals. This was detected by excessive end-play and was checked each time the points were replaced. When the end-play fell out of spec (ie, > .020" )the distributor was plucked out and replaced by one locally rebuilt by the dealer, the purely nominal charge (typically less than $10) listed under 'Other Work - As Required' on the standard Volkswagen work-order. (A large kit of spare distributor parts was provided by the Robert Bosch Co. and the chore of rebuilding carbs and distributors, typically a dozen at a time, usually fell to one of the shop's 'boys' -- like me (in the mid-1950's) -- although some of the 'boys' might be thirty years of age :-)

One disadvantage of using the distributor shaft to drive anything else was accelerated wear of the bronze scroll gear. This part was good for up to 100,000 miles when driving only the distributor but the Vertex magneto (for example) increased the load to the point where the gear was supposed to be replaced after only 500 hours.

If you'll go to my blog (bobhooversblog.blogspot.com) and enter 'ignition' as the search seed (in that little white box on the upper left of the screen, the articles, photos & drawings may provide additional insight. Additional drawings & photos will be found in the Files archive of the 'chuggers' Group on Yahoo, in the Dynamo folder, in the Engine file.

If all you need is a SMALL amount of power you may wish to consider using a permanent-magnet motor as a dynamo. Hanging one of these out the window of your car (on a suitable mount) is not only educational, it can be a lot of fun. In use, the thing is usually attached to a convenient inspection plate, suitable strengthened, and provided with a simple circuit to rectify (if necessary), smooth and regulate the output. Balsa or foam may be carved to provide a streamlined housing; a slotted disk or even a model airplane propeller have been used as the turbine.

-R.S.Hoover

-(KA6HZF)

Posted by Collin on Tuesday, April 29, 2008 @ 08:49 PM:

Bob,

Thanks for your input. I have read many of your articles. Lots of good info.

Collin

Posted by eugenio on Wednesday, May 7, 2008 @ 02:53 PM:

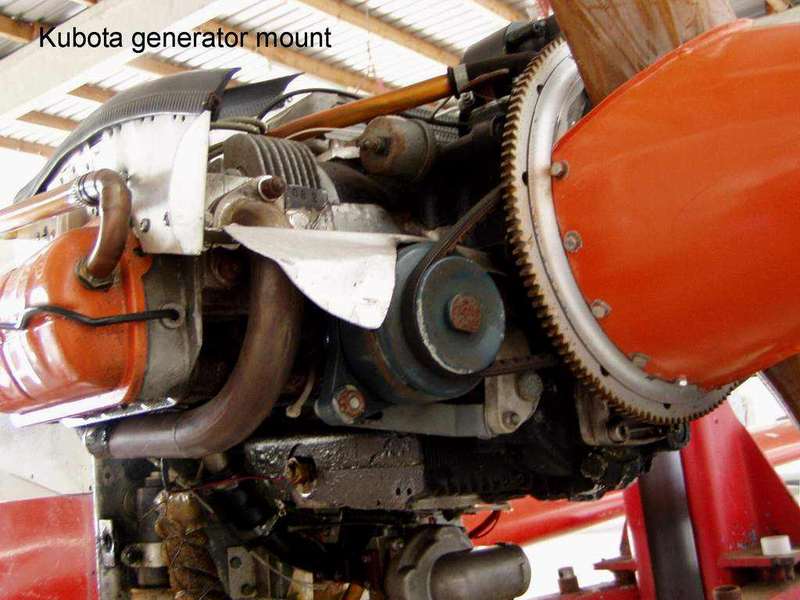

If you look on the German CFI Website you can find the generator modification approved by LBA (prepared by Patrick) that allow the installation of a Kubota generator in the cowling without the need of modifications (just a little cut in front of the cowling) There is no need to reinvent the wheel.

ciao

Eugenio

Posted by SteveBeaver on Wednesday, May 7, 2008 @ 05:19 PM:

I was able to find "Generator.pdf", but it contains only an electrical schematic, not mechanical drawings. - Can you tell me more exactly where to look please?

Posted by Collin on Thursday, May 8, 2008 @ 04:51 PM:

Posted by SteveBeaver on Thursday, May 8, 2008 @ 06:12 PM:

Thanks Colin, but this shows an RF5 installation, or and RF4 converted to electric start + ring gear. It is still not clear to me what would drive the Kubota generator in a cable start, RF4 Rectimo installation.

Steve

Posted by eugenio on Tuesday, May 13, 2008 @ 11:50 AM:

You must remove the hand starter if you want to put the generator on. But this has to be done also if you install any fancy device in the distributor hole. On the CFI-D website you can find "Technische Mitteilungen-CFI_FA_01_95_Certification RF3RF4 Generator" the PDF documents contains also the flywheel drawing, you remove the spinner bulkhead and put the new bulkhead/flywheel. It's easy, and no great modifications of the cowling.

cheers

Eugenio

Posted by Antti on Thursday, March 3, 2011 @ 07:33 AM:

Hello guys,

A couple of questions concerning this old thread. At first, I am not able to find that file "Technische Mitteilungen-CFI_FA_01_95_Certification RF3RF4 Generator" Eugenio told about. Under Technik-Elektrik I can find a Generator-Anschlussplan, but there is no drawing about the flywheel construction. Am I stupid or what

The other thing, where in Europe can you fing this type of generator? All I found are newer, bigger types. I can find these thingies all around the US, but considering the freight and taxes, this sounds like a not good option. Perhaps I could find one in a local Kubota-store, but perhaps they are not on the net.

-Antti-

[Edit by Antti on Thursday, March 3, 2011 @ 07:33 AM]

--------------------

***** RF4D OH-370 - RF4D OH-371 - RF4D OH-373 - RF5 0H-386 *****

Posted by Collin on Friday, March 4, 2011 @ 04:53 PM:

Hello,

Here is a picture of Engenio's Flywheel he made.

Posted by eugenio on Friday, March 4, 2011 @ 04:56 PM:

I found the generator and related stuff here in Italy from a Kubota Dealer, so it should not be difficult to find it also in your country. For the SB, below the instructions to the right link:

http://www.cfi-ev.scram.de/D/Index/index.htm; then click on Technic; click on the RF4 image on the left top; click then on >Technische Mitteilungen-CFI_FA_01_95_Certification RF3RF4 Generator< and the PDF will open.

The generator is very common in France between the RSA community, I found them once in one of their meetings.

ciao

Eugenio

Posted by eugenio on Friday, March 4, 2011 @ 05:09 PM:

One more thing.... Yes I confirm here in Europe you don't find it on the net, but if you ask a Kubota dealer he can find it. The generator PN is 15331-64011 and the regulator is 15533-64601 superseded by 19267-6460-1.

Be adviced that they are expensive, about 250 euro generator + regulator, so if you can find it in the US maybe you can have a better price also with shipment and taxes.

Eugenio

Posted by Antti on Monday, March 7, 2011 @ 04:25 AM:

Thanks guys for your help. This really seems to be a proper way to do it. What would be the cost if "some experienced guy" made the wheel and the brackets for the installation?  Even with the threads for spinner which I don't see in Collin's photo.

Even with the threads for spinner which I don't see in Collin's photo.

I think there shouldn't be no problem with the authorities as this has been certified in Germany.

Interesting indeed. Somehow I haven't seen this before. Perhaps because I am allergic to starter ring modifications on RF3/4 s.

-Antti-

[Edit by Antti on Monday, March 7, 2011 @ 07:46 AM]

Posted by Jorgen on Monday, March 7, 2011 @ 05:56 PM:

Also, the drawing on page 10 is missing 3 PCD numbers on the left side of the page. What are they?

Lastly, what does this setup weigh? Discounting a battery, just the dynamo, regulator, propeller drive wheel and brackets.

Here are some pictures of Bob Brock's charging system that the passed owner John Buckner installed. I believe it is adapted from a snowmobile.