Quick links: E.N.M.A. Tigre LOM332 Lycoming

Update 2: The LOM 332 page has ben completely updated with a lot of information on the care and operation of the engine. There is some more to come but I hope that even now this new data will be of use.

Update: Larry Ernewein has recently updated his two documents on the ENMA Tigre engine. Please visit the "Downloads" section of this website and look in the "Engine documents" folder for :

The original Engines:

The Jungmann was originally manufactured with a 4 cylinder inline of 80 HP or so, manufactured by Hirth, Walter, ENMA or Hitachi. I am not aware of any Hitachi engines still flying but there are numerous examples of the other still giving sterling service.

The Hirth engine is a jewel, in many ways years ahead of it's time. It had many clever features such as hollow cylinder hold-down studs inside of which the pushrods ran, a multi-piece crankshaft bolted together and a ball bearing bottom end. Unfortunately, these fine engines are now becoming difficult to keep running and many people consider them museum exhibits rather than practical airplane engines. Certainly if I had one, I would polish it and display it in my study!

The Walter Minor IV is very similar in appearance to the Hirth. Made by Walter Motor in the Czech republic, this engine is quite conventional and straight forward. I owned the 6 cylinder version for many years installed in my Zlin 226T and can testify that it was quite reliable and smooth. The Walter is also a fairly light engine compared to others of the period. Spare parts are reasonably available and I have all the maintenance manuals, operators guide and tear-down sheets. I still have quite a number of spare parts too. The Walter is still a tinkerer's engine. You will spend a lot of time tweaking and twiddling this and that to make it run consistently, but given a little effort of that sort, it is a pretty nice engine.

The ENMA Tigre (Tiger) engine is the subject of much debate in Bücker circles. When I was contemplating installing one in my Jungmann, many people told me I was crazy. It's a death trap. "You might as well shoot yourself in the head", one person told me. Others, particularly those who have a Tigre powered aircraft tell a different story. Properly looked after, it is a strong and reliable engine. My research revealed that there have been a number of fatal accidents in the USA widely attributed to the engine but on closer examination, I found that it really wasn't the engines fault. There was the aircraft in Maryland that had a prop. strike. A new prop. was installed but the front centering cone was omitted. Not too surprisingly, the nose of the crank broke off in flight. Another aircraft has a Tigre come completely apart but the logbook contained a warning (in Spanish) that the engine was for display purposes only and none of the internal components had been safetied!

One thing about about the Tigre that can't really be argued about is the weight. They are heavy! I will look up the exact figure (I have it somewhere) but I seem to remember its a whopping 370 lbs or so. Even with 15 lbs of lead in the tail, Tigre Jungmanns tend to be nose heavy.

The Spanish Jungmann were built with 125HP engines. There is also a 150 HP version which was not intended for the Jungmann but which is the engine most often seen these days. (It was originally intended for a license built Dornier high wing single) Unfortunately, you also need a new prop. if you change to this engine. The 125HP prop. will cause the 150 engine to make less than 125HP and the ground adjustable prop. intended for the engine makes an already nose heavy aircraft into a wheelbarrow! A number of people have told me that the 125HP engine is much smoother in operation than the 150.

Among the recommendations I have heard to promote the safe operation of a Tigre are these (Do you know of any more ?):

- Don't use fancy grease in the rocker covers. Use plain old brown Aeroshell grease.

- Be very careful to use the correct torque on the cylinder studs. Too tight and they break, not tight enough and they work harden and then break! Adam Larson has (or had) new and improved studs available. Ernie Streifthau suggests using a "pal" nut to keep the nuts in place and says he has not had any problems since installing these.

- The ignition system is very weighty indeed. The brass conduit can be removed to save its weight and Bill Hill, of Hamilton, VA has found that the all inclusive electronic distributor from a Toyota Camry will fit right in the magneto housing of the Tigre. Bill replaced the Toyota bearing with a "sealed for life" bearing and for about $50, had a feather-weight and modern ignition system.

- The automatic advance mechanism can cause a very rough idle. Bill suggests a short length of tubing slipped over the magneto shaft holds the counter weights out a little and makes the engine idle smoothly again.

- It is common practice to replace the Spanish carburetor with an Ellison Throttle Body Injector (The EFS4-5 model). The Ellison should be mounted on a short (2") extension to act as a plenum.

Here is a study of the ENMA Tigre that was written by Larry Ernwein and Karl Pfister. In their opening disclaimer, the two state that they are not licensed mechanics, but just pilots who have spent a lot of time maintaining these engines.

While that may be literally true, I would suggest you will have to go a long way to find a better example of the maxim that one doesn't need to make a living at something, to be a professional! Please click on the image below to read this thorough document.

More modern (well slightly) engines

If you want to install a newer engine, there are two choices: A Lycoming of some sort or an LOM.

The Swiss may (or may not) have been the first to replace the original engine with a Lycoming in the aircraft they re-christened the Lerche (Lark). The aircraft was fitted with new wings of a nearly symmetrical airfoil section and a Lycoming O-320 of 150 HP. A new cowl was installed with clever air outlets on the sides. The Lerche was intended to keep the Jungmann in the competition arena for a little longer against the Zlins and Pitts beginning to appear in the 1960s.

In the USA, many Jungmann have been converted to Lycoming power. There were two main sources of the conversion and a number of "home brew" solutions. My least favorite (by far!) is the one seen in the movie "The Three Amigos" and flown in that film by Jim Franklin. The engine is mounted about in the middle of the firewall so that the thrust line is at least a foot lower than the original. I think it looks terrible!

Joe Krybus makes a conversion that offers a cowl very similar in appearance to the Lerche cowl although the cooling inlets are a little square. Wood Menear at one time made conversions that had a very nice cowl. He carefully maintained the correct side profile so that looking at it from the side, you could not tell it was an opposed engine. From above, it had the usual wide Lycoming appearance.

Another popular way of dealing with the cowl problem (pioneered by Wood Menear again) is to keep the original cowling but stick the cylinders out through the sides, J3 style. This provides cooling adequate for an O-320 but not the larger engines. I think this is my favorite conversion. Brian Karli's recently completed Jungmann has this system and weighs only 840 lbs. Woody Menear's first Jungmann was widely considered to be an exceptionally fine flying Jungmann.

The performance and reliability of a Lycoming powered Jungmann is excellent. A spectacular rate of climb is achieved and of course, these engines are about as reliable as an airplane engine can be made. The only two drawbacks are that the look of the aircraft is changed and the visibility over the nose, particularly from the front seat is reduced.

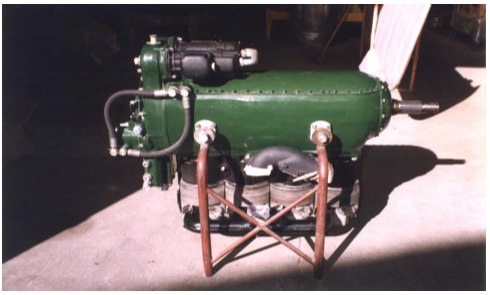

In recent years, LOM engines have again become available in the West. The LOM332AK engine is the 4 cylinder unit that is now being installed in several Jungmann. These engines are produced by the the company that evolved from the Czech Walter company and have a number of very significant advantages. They are:

- Light weight

- Very modern (Overhead cam, supercharger, multi point sequential fuel injection.)

- Unbelievably smooth. - More like a Honda Civic than an airplane engine.

- Use exactly the same engine mounting points as the Walter Minor and very similar to the Hirth and Tigre.

- Very fuel efficient

- Supercharger has two gear ratios so it can be operated supercharged or (essentially) normally aspirated.

- Built-in inverted fuel and oil system.

- 2000 Hr TBO and excellent reliability.

They have some significant disadvantages too.

- Having two supercharger ratios, they really need a propeller with at least two pitches! In other words, the use of a fixed pitch prop. is even more of a compromise than usual.

- The maximum power output of 160HP is obtained at 3000 RPM, meaning that the prop. you will need looks like a tooth pick compared with the massive piece of lumbar a Tigre swings. </span

- The smoothness and lightweight come at the cost of reduced climb performance compared to a 180 Lycoming.

This is the engine I have chosen for my project and you will find many pictures of it in the Pictures/Engines section of this website. I will detail the installation methods I chose in the "How To/LOM engine installation" section as soon as I can.

There is a great deal of information on the Moravia website. They are one of the importers of the engine.

Back in 1996, I had the chance to fly Wood Woodward's LOM Jungmann. I wrote an article about it for the Bucker Club newsletter but it was mangled out of all recognition. This is what I originally wrote:

Woody Woodward's LOM Jungmann.

On Wednesday, September 25th 1996 I was traveling on business through Tennessee. I called on Woody Woodward in the hopes that I might see his Oshkosh award winning Jungmeister and his LOM powered Jungmann. Not only did I get to see them, I was given the privilege of flying in the Jungmann. What follows are my impressions of the plane which I submitted to the Bücker club newsletter at the time. It was so mangled in the newsletter, it was just about unreadable so here is the original text:

Now this is not exactly an unbiased report. I really wanted to like the LOM since I had already committed to using one myself and at the time, I owned a Zlin 226T and was very fond of its Walter Minor engine.

With the super charger engaged, and the mixture set to the starting position, the engine turned over vigorously. After a few blades the mags. were turned on and the engine just changed from not running to running. – It was as simple as that. There was none of the coughing, vibrating, settling down and finally smoothing out nonsense we usually put up with. In less than a second it was running like it had never been switched off.

Lining up on the runway at Woody’s grass strip, the throttle was advanced to full power (2750 R.P.M.) and we were on our way. The take off roll, while by no means prolonged was certainly not the abbreviated affair that a 180 Lycoming produces. We rolled a little with the tail down. We rolled a little more with it up and the stepped into the air. I suppose it was about like a PA11 or a light Citabria. The indicated rate of climb was 1000 fpm (two up, one third fuel and 75° F OAT) Once aloft, the R.P.M. was reduced to 2400 and we flew around for a while at about 95 kts. I rolled the Jungmann on its side and tried to tell if the in-line cowl had changed the knife-edge capabilities but if it had, it was too subtle for me. In slow rolls, point rolls and other maneuvers, I could not really detect any significant difference between the handling of this aircraft and the Lycoming Jungmanns I have flown. I did notice what I thought was a reduction in yaw stability, though, presumably caused by the long Krybus cowl. What was very different, however, was the feel and the view.

The engine was extremely smooth. I may be odd (ask my wife) but that smoothness really added to the pleasure of flying the aircraft. Somehow those slow rolls seemed more magical than ever without the usual throbbing vibration from up front. The visibility over the sleek in-line cowl was also a real bonus. I like to give rides and share the Bucker magic with other pilots, and I especially like to fly with my wife Jeanne. In a Lycoming powered Jungmann, the front seat offers only a poor imitation of the view from the pilot’s seat. In this aircraft though, the view from the front seat was (except for the top wing) very nearly as good as that from the back. The Bucker experience was very little diminished.

In conclusion, if you have a Bucker because you revel in its superb light and delicate handling, its balance and its grace in the air, you will find that installing an LOM 332 will provide a significant enhancement to your enjoyment. If your pleasure comes from the adrenalin rush of a big Lycoming and the thrill of climbing out at 35°, better stick with Pennsylvania’s best.

My most sincere thanks to Woody Woodward for the opportunity to fly the Jungmann. It was the most enjoyable flight I have had in a long time.

SJB

Sept 1996

P.S.

Woody has since sold his Jungmeister and converted the Jungmann back to Lycoming power. He thought the LOM engine was just too wimpy and missed the rate of climb he enjoyed with 180 HP!

Moravia have sent me an LOM exhaust system to trial fit on the Jungmann. I am happy to say it fits perfectly. These pictures show it without the engines baffles in place but it is designed to accommodate them. Moravia expect to sell the exhaust system, ball joint and tail pipe for about $800.

From Brian Karli, these two TIGRE documents originally by Jose Martin or Martin Aero Products are titled "ENGINE MANUAL" and "Procedures for starting a preserved engine". The manual reference diagrams which I have in too poor a resolution to reproduce. It makes some sense even without them. Thankd Brian!

This 53 page M$ Word document is a translation of the Siemens SH14 engine found on the Jungmeister. If you have any difficulty downloading it, try clicking the Right mouse button and selecting "Save target as" from the pop-up menu.

This one is a translation of the ENMA Tigre troubleshooting guide.