We have a Hirth 504 engine for sale and maybe someone is looking for one . The engine has the accessories missing except the carburetor which is in complete and in excellent condition and has two of the cylinder heads welded . They are usable now but I must clarify this . They broke because of over-speeding. The rest of the engine is in very good shape in fact , so a nice project to get an engine .

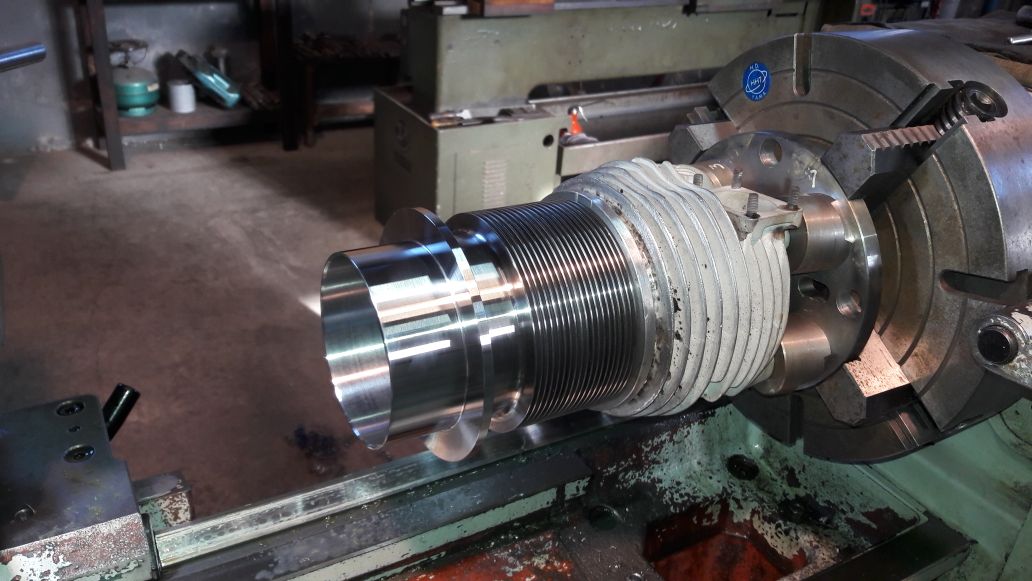

Also I wanted to let you know that we are manufacturing complete cylinders for the Siemens SH-14 , with higher quality , even better than the originals . We use the exact alloy , the special forged alloy taken from Bohler from Germany . These cylinders are probably better than the originals due to the many controls we do on them . Each cylinder is made from a solid bar of forged steel . They are machined milled to 106 mm . Then they are screwed into the cylinder head , heating the head and the cylinder under Nitrogen to freeze it and with a special device made exclusively for this process . After that , they are machined milled to 107.85 mm . The last step is the finest brushing to the exact 108 mm . So , they are delivered in 108 mm , ready to be placed .

Now we completed 3 sets , and one is available for sale .

Regarding the cylinder heads : They are cast WITH THE EXACT ORIGINAL ALUMINUM ALLOY . Then they are machined milled for the valve seats , guides and also the insert of the spark plugg . Everything is NEW . The valve seats are ribbeted based on the American norms .

All the heads have the intake and exhaust holes rectified ! , you can't find even a micro imperfection on them . The original heads come with many imperfections from the foundry .

The ceiling of the heads are also rectified ! : we use a special tool made especially for this , so all the ceiling heads are exactly identical in measure and finish : this brings THE ABSOLUTE EXACT COMPRESSION TO ALL THE CYLINDERS . This step is done with the cylinders screwed in . The original heads were placed without this process.

Every head is controlled by ink and ultrasound . An RX is done after screwing in the cylinder .

All the cylinders and heads will be delivered with the metallographic alloy analysis certified .

Every head has a port exactly over the intake valve . You can put a Bendix distributor (picture attached) to prime the seven cylinders at the same time for starting the engine in the first attempt . This system replaces the air compressed system to start them . It is very easy to use and the start ups are absolutely easier.

We are also manufacturing the manual starter system for Siemens with a perfect quality and finish . Easy startups without danger nor help .

We can also supply new high compression pistons and new piston rings , also new valves . If the client ship the valves , pistons , rocker arms and valve sticks , we can ship the cylinders ready to place , complete

I'm attaching pictures .

Kind regards

Ricardo Birsa

US1 Exports

Website : www.us1exports.com

Email:

Alberti 857 (1642) San Isidro

Buenos Aires , Argentina

011-549-1-1-4970-9177 (Whatsapp)

011-541-1-4740-6346

Skype : us1exports