The director of LOM's piston engine division Petr Prokop replied not only to thank me, but to point out that the baffles between the cylinders of my engine were incorrect. In fact he did not recognize them at all. (My engine is new/old stock and was built long before Petr's time.) He offered to send me a set of the newest design baffles. The cost was very small, and the shipping wasn't bad, but the cost of wiring the money was horrible. It seemed to make sense to make better use of the bank fees.

My engine runs well, but compared to other LOM engines, particularly Richard Epton's Bestmann, it is not quite perfect. The mixture control seemed to be fairly critical and even when adjusted as well as possible, and there were certain RPM bands that were less smooth than I would like. Consulting Mr. Prokop again, he told me that my fuel injection system was of an old design which has since been updated several times. He made the offer that if I were to send it back to the factory, they would update it to the latest version and would test and callibrate it for me. In the end, I decided to send the whole system. The injection pump, throttle body and the four injectors.

This turned out to be a lucky move. Factory testing showed that one of my injectors was not within specifications. After the components were brought up to date they were bench tested and callibrated before a comprehensive run on the compny dynamometer. I reveiced everything back via DHL only three days after the work ws complete.

Newly updated pump

The pump, injectors and throttle body were installed in about a day and it was ready to test fly. Did it make a difference? You bet it did. The idle is slower and completely smooth witout the slightest misfire. The throttle response is now completely linear throughout the range, and the engine is electric motor smooth at all speeds. It was worth every penny of the modest cost. It makes sense. With one injector out of spec I suppose that the mixture could be adjusted to make three cylinders happy, or one cylinder happy, but not all four

The service from the factory was fantastic. Everything needed to reinstall the parts was provided. Gaskets, nuts, washers, safety wire. - Everything. At most flyins I attend I am asked 1) Is that a homebuilt? 2) What type of engine is that? 3) Where do you get parts? I now have a good story to go with number 3 at least :)

Oil cooler

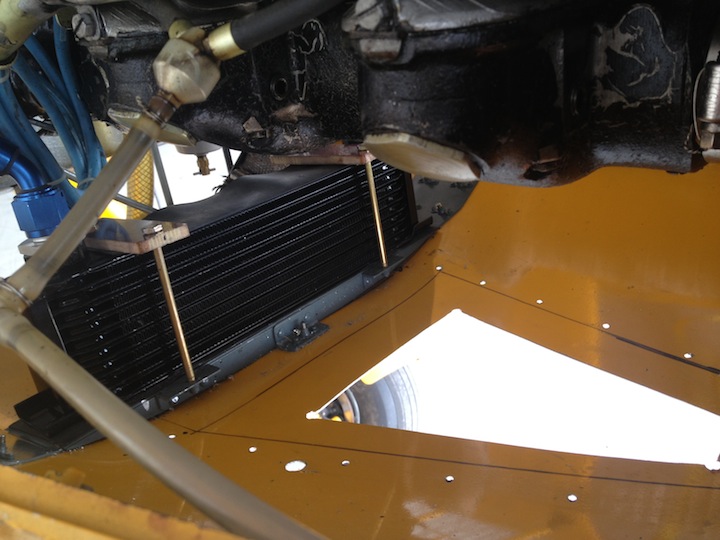

While the fuel injection system was away in Prague I took the time to work on an oil cooler. The oil temperature was OK, but I would like to see a few degrees less on very hot days.

I made a bracket to fit inside the lower cowl, mounted the cooler and cut a small vent in the underside. I started small and can open it up if needed):

Then I made an airbox to direct air through the cooler:

Early indications are that it works as desired. Oil temp is about 10 degrees lower than before. I think I will enlarge the inlet just a little and call it done. - Not that any restoration/build is ever really done. There is always something to do :)

Update:

Making the inlet bigger didn't have much effect on the oil temperature so I tried adding a small lip, or sccop to the inlet. This had a huge effect. Even a small (2 CM) scoop dropped the oil temperature by a further 35 F. I just made a two hour flight on a very hot day (95 F) and saw an oil temperature of only 145 degrees. Now I will start closing the opening up again to determine the minimum practical size. 145 F is a little too cool.