The springs in our landing gear legs can get old and tired. Combine this with the installation of a heavier engine, and perhaps a heavier prop and it is no wonder that ground handling starts to suffer. Several people have replicated the springs. Sometimes the replicas worked well, while other times they looked promising only to sag after a few months. Not all landing gear legs are exactly the same either. Spanish/Czech & German are of slightly different dimensions. I suppose that expecting the original springs to work correctly in 2014 is like expecting a piano to remain in tune for 75 years :)

Gilles Tatry has taken a completely different approach and has kindly shared this story about his efforts to date. Gilles emphasizes that this project is not yet complete. There is still much work to do and it may, or may not lead to the availability of a retrofit kit at some time in the future.

--o0o--

As usual, a part of my Jungmann winter care has been dedicated to the landing gear. We all know that this component is one of the main objects of care, and sometimes sources of concern, of our beloved aircraft.

Usually the springs subside and the gear lowers with time and landings, and some length of spacers must be added to get back to the original ground attitude. Some Jungmanns stand high, some stand low. The attitude also leads to very different ground behavior as wheel toe-in is directly linked to the gear height. Hangar handling may become difficult, if not impossible for a single person. The tires may wear incredibly quickly, idle power may become insufficient for taxi, and, worse, landing may become much touchier, especially on paved runways.

Fine adjustment of the gear height is essential, and the only way to do it is changing the springs or adding spacers. This requires the landing gear to be taken apart, which may lead to paint or covering damage. Once removed, putting the axles again in position is painful if the holes are not perfectly aligned, which is common on CASA aircraft.

Moreover, the springs often rub against the internal rod, the housing or both. The movement sometimes is not free, and even painfully noisy. Sometimes the guide bushings get play, sometimes (often!) the seals leak... The landing gear easily hits bottom: it may damage the fittings which, with time, may break.

When I was making spacers on a lathe, a friend of mine, expert in race cars and motorcycles tuning, told me "Why the hell don't you ask Fournales to replace your f..g springs by gas struts?"...

Jean-Pierre Fournales had been in charge of designing the Concorde landing gear struts then imagined miniaturizing their design to benefit the highly demanding suspensions of motocross bikes, his passion at this time. Since then he has become famous as an eclectic expert of very high-tech oleo-pneumatic shock absorbers in the world of car and motorcycle racing, mountain bike, cars, trucks, RVs, ATVs, aeronautics, industry, medical equipment and even prosthesis: www.fournales.fr

As a matter of fact, my glider club tow aircraft, fitted with three Fournales shock absorbers, has endured tens of thousands of repeated landings on our bumpy grass runway for many years, with absolutely zero maintenance. Not a leak, not even once a need to readjust pressure. I calculated that such a number of landings would mean flying my Jungmann for about 500 years, which made me quite confident with Fournales technology standards.

Jean-Pierre Fournales was at first not very enthusiastic as obviously my request would be more of a burden than a money-maker for his enterprise. But he eventually got highly motivated by the technological challenge and made the calculations and drawings.

My specifications were:

- Fully reversible and invisible modification

- No subsidence, no leak, no play, no friction, no noise.

- Height and spring rate easily adjustable.

- Damping law optimized to prevent bounces at landing and improving ground behavior.

- No bottoming out.

- No maintenance.

- Less weight.

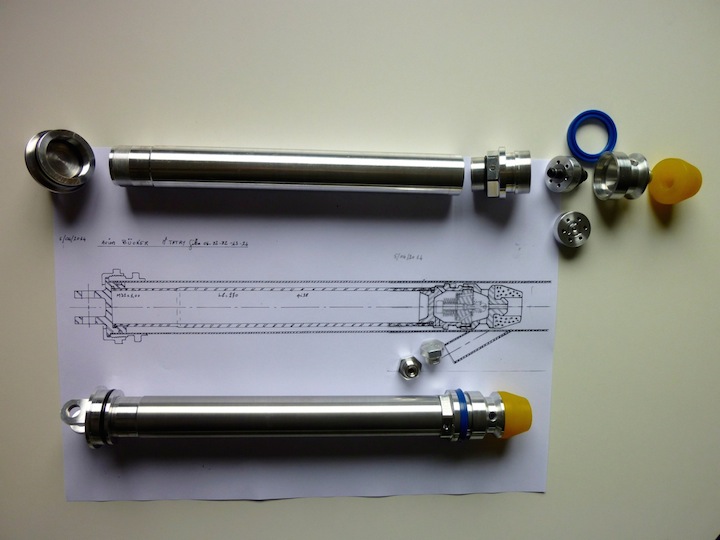

The result was very clever: Jean-Pierre Fournales redesigned the whole gear leg as an oleo-pneumatic strut itself. The steel spring was just replaced by a volume of air acting as a gas spring. The only modification to original parts is to chromium-plate the sliding part of the leg, to allow the use of high-technology, high-pressure dynamic seals.

The bronze guiding parts were replaced by new ones made of aeronautical 7075 alloy, light and strong. Both are fitted with up-to-date high-tech seals and sliding strips, sustaining high loads with low friction.

The sliding one, screwed at the upper tip of the sliding leg, is also a piston which compresses air inside the upper part of the leg. It is fitted with a valve which allows oil through when the gear is compressed, but restricts oil flow to control bounce tendency when the gear extends.

The leg-to-fuselage fitting has been removed with its plunger rod. A new one made of 7075 replaces it. It is fitted with a seal which makes the leg perfectly airtight and a rod which adjusts the volume of air available for compression. The volume of air acting as a spring is adjusted to get a non-linear, progressive spring rate: flexible and comfortable at the beginning, then getting stiffer at the end of the stroke, which ends on rubber as the tip of the rod is fitted with a 30mm elastomer bumper: not only any metal-to-metal bottoming is suppressed, but it also allows one to fly back home in the event of a deflated leg on one or both sides - just in case.

The rod tip is also equipped with a series of check-valves, to provide damping for small gear movements (for better ground stability) but allow full range energy absorption in case of hard landing (like De Carbon desert raid schock absorbers)

The special oil is let in by the original oil neck, the plug of which is replaced by a new one with a tiny invisible air valve inside, and a pressure sealing washer. The only one clue of any gear modification is a hardly visible 1 mm hole drilled in the center of the plug to allow a needle through the valve for pumping air in, for height and spring rate adjustment.

I weighed the removed parts, and those which replace them: the added parts weight is 25% of the removed parts one, and the saved weight is more than 3 kg, or 7 lb. "Cerise sur le gâteau!" (Cherry on the cake)

I just began a test period and the first results seem good: very comfortable and stable on rough grass, the Jungmann keeps almost level during high-speed steep turns. No more bottoming on bumpy grass except the tail wheel (to be modified by Jean-pierre Fournales next winter?)

At this time, we are wondering if it would be possible to produce a kit which would fit any Jungmann, as not two of them are exactly similar: even my right and left landing gear legs have slightly different dimensions!

I will keep you informed...

Gilles