I have woven several sets of tailwheel steering cables for Bucker owners over the years. It's a lost art and a rather time consuming process. At one of the Bu&BBQ gatherings, Greg Stringer mentioned an ingenious modification that Woody Menear designed to eliminate the woven cable altogether.

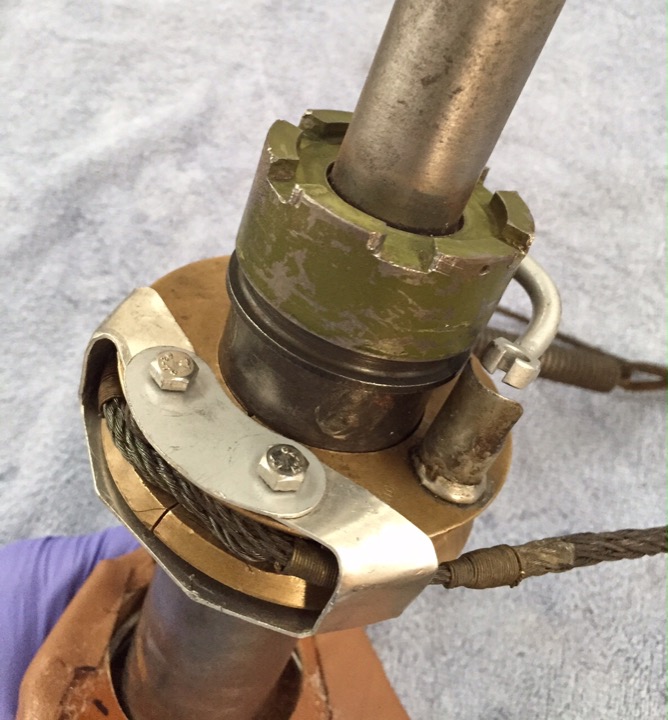

As many of you are familiar, two woven cables curve around the brass/phenolic collar on the tailwheel shaft.

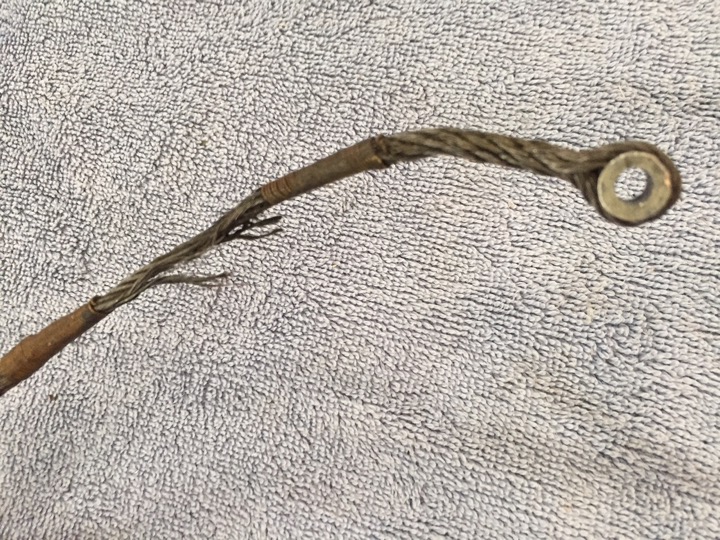

As the tailwheel turns, this cable will rub enough times to eventually fray. This is exactly what happened with my Jungmann cables.

A Nicopress sleeve is a wonderful invention. After spending 45 minutes weaving one cable end, the lure of modern convenience was strong. Why not make the new cables with Nicopress sleeves? As you can see below, the Bucker tailwheel collar is not wide enough for two of the clunky sleeve. See why the cable was woven...?

There would be no room for a second cable. Plus, look at the awful bend the cable would have to make.

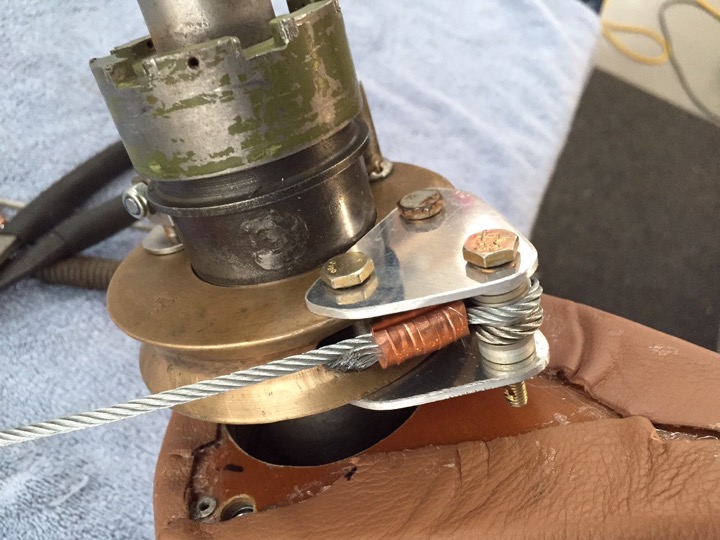

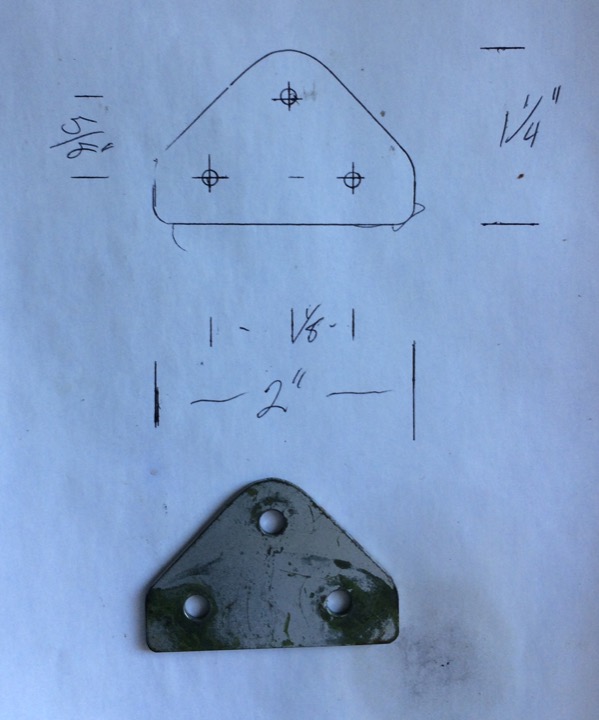

Woody designed a simple bracket to move the Nicopress sleeve away from the collar.

From a side view, you can see it better. Both cables meet in the center.

Because of the bracket, the cable makes a gradual bend around the collar.

Excuse my hand drawn drawing, but if you want to make one, here are the dimensions. The center hole is 5/8" in from the collar bolts.

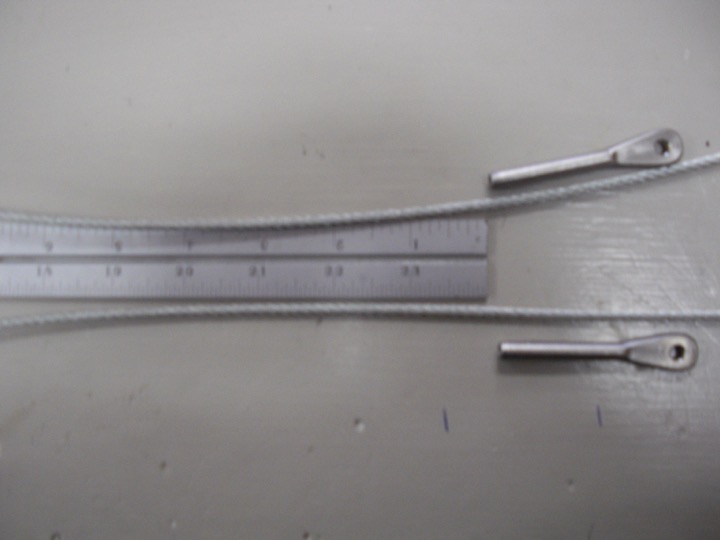

Jeff Rowland came up with another way to solve the tailwheel cables issue. He moved the Nicopress sleeve back past the steering collar. Now, the cables have room for flexing. He has been using this method for almost 10 years and has not had one failure. He found out that 1/8" in cable worked the best.

There is also weaving at the spring in the middle of the cable. If you do not want to replicate the weaving, you can have ball ends swaged in lieu of the weave.

These ball ends require a special machine to crimp the ball to the cable. Specialty cable companies have the machine and Aircraft Spruce offers the service. We are fortunate in the Bucker community that Jeff Rowland has the machine too and has offered to help make replacement tailwheel cables.

As for the other end of the cable, you have options. Original turnbuckles are getting hard to find these days. If you have your old ones, you could weave them back into your new cables. Another option was seen in both the Menear and Rowland designed cables. They eliminated the turnbuckle altogether and replaced it with a modern swaged end.

When making the new cable, Jeff shortens the end by 1/4 inch. The spring tension does the same thing as the turnbuckle - it keeps the cable tight.

Here is a picture of Jeff's installation.

In conclusion, it is possible to make new cables without teaching yourself how to weave. Use your old cables as a guide. Good luck. If you need help, feel free to contact me or Jeff:

Brian Karli - This email address is being protected from spambots. You need JavaScript enabled to view it.

Jeff Rowland - This email address is being protected from spambots. You need JavaScript enabled to view it.

Cheers

Brian

Brian